Four Burning Questions about Needlepoint Bipolar Ionization, Answered

Should you add needlepoint bipolar ionization to your HVAC design toolbox?

I’m usually skeptical about air purification claims in general, since these technologies often lack data and are usually supported by anecdotal evidence at best. However, after reviewing the research, and using the technology successfully on-site, I’m convinced that needlepoint bipolar ionization has a place in HVAC design, and can reduce project installation costs and energy use, while improving indoor air quality (IAQ).

What is needlepoint bipolar ionization?

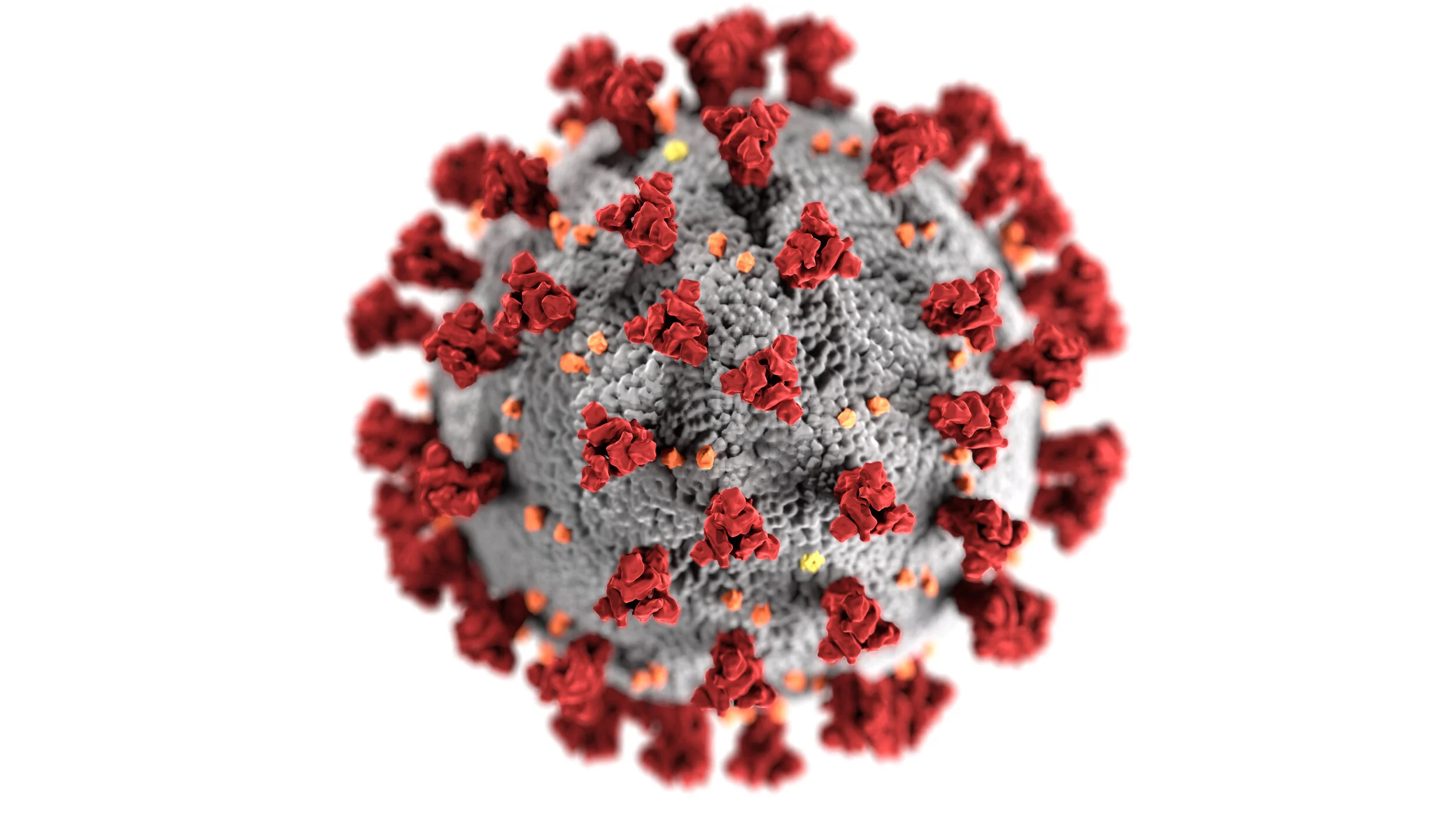

Needlepoint bipolar ionization is a commercially available technology that produces a stream of ions that can capture gaseous and particulate contaminants in the air, including volatile organic compounds (VOCs) and odors. Negative and positive ions are produced when electricity is applied to a tube with two electrodes, and which in turn react with water vapor and oxygen in the air to create free radicals. The free radicals can kill microorganisms and break down odors, improving indoor air quality.[1]

Typically, a module is mounted inside the air handling unit at the fan inlet. Media filtration is still required.

By addressing contaminants at the source, the potential cost and energy savings come as a result of reduced outside air ventilation rates.

How can we reduce ventilation rates and still meet code?

The Indoor Air Quality (IAQ) Procedure in ASHRAE Standard 62.1 allows reduced outdoor air intake rates in conjunction with engineered air purification technologies. In turn, this allows reduced sizing of equipment, resulting in lower first costs, reduced energy usage, cleaner coils, and better space humidity and temperature control while maintaining acceptable levels of indoor air quality.

Instead of using “brute force dilution” of contaminants via increased outside airflows, required outside airflow rates can be reduced by directly addressing the contaminants of concern. Bipolar ionization breaks down harmful VOCs, kills mold, bacteria, and viruses, improves filtration effectiveness by particle agglomeration, and oxidizes odorous gases. For instance, a recent University of Michigan study concluded that cold plasma (ionized particles) killed 99.9% of airborne viruses.[2]

The CoC design level of acceptability is “equal to or less than” the concentration which would result using the Ventilation Rate Procedure. Target concentration levels should be indicated in the design documents.

What about reducing CO2 in the space?

Even though bipolar ionization improves indoor air quality by reducing Contaminants of Concern (CoC), this method does result in higher carbon dioxide (CO2) levels than would be achieved with the ASHRAE 62.1 Ventilation Rate Procedure. CO2 is not considered a Contaminant of Concern by ASHRAE. However, in the past, CO2 has been used as an easily measurable proxy for indoor air quality, since a higher level of CO2 generally indicates a higher concentration of other contaminants.

ASHRAE does not specify a recommended CO2 level, beyond stating that “CO2 at very high concentrations (e.g. greater than 5000 ppm) can pose a health risk”. ASHRAE further states “Note however that CO2 concentration is not a good indicator of the concentration and occupant acceptance of other indoor contaminants, such as volatile organic compounds off-gassing from furnishings and building materials. Thus, CO2 concentration is not a reliable indicator of overall building air quality.[3]”

Still, I recommend a cautious approach in designing to a much higher CO2 level, since future research may reveal more clear information about the effects of CO2 with regards to indoor air quality.

What about harmful ozone?

Bipolar ionization has been around for decades. The older style of generators used perishable glass tubes and would also create potentially harmful ozone during the process. However, needlepoint modules, developed in the mid-2000’s, do not create harmful levels of ozone. They are tested in accordance with UL 867, which limits ozone to 0.05 parts per million by volume.

Needlepoint bipolar ionization should not be confused with corona discharge ionization.

Recommendations

1. Use cautious and reasonable outside air reductions, where allowed, to reduce energy consumption and installed costs. Manufacturers assert that bipolar ionization can reduce ventilation rates up to 75% in non-healthcare applications; however, I caution against cutting dilution rates too aggressively. Though CO2 is not listed as a contaminant of concern for indoor air quality, I am hesitant to increase levels significantly above normally acceptable levels. The best indoor air quality still results from a combination of adequate outside air, distribution, filtration, and treating contaminants of concern directly.

2. Specify that any products meet UL 867 and UL 2998 certifications to ensure no harmful ozone is produced.

3. Use the technology where it makes the most sense. For instance, in a historical rehab with limited room for ventilation ducting, this technology can significantly reduce duct sizes. Another great application would be for a building in an area with poor outside air quality.

4. Measure IAQ directly. Consider including a “before and after” air quality assessment, or install permanent contaminant monitoring equipment for larger projects.

5. Use self-cleaning technology to minimize maintenance where available.

6. Use alarming to ensure that facility staff are aware of any problems with the IAQ modules. For instance, some modules come with a set of alarm-output dry contacts to alert staff if the unit is no longer energized.

[1] “Standard 62 IAQ Procedure: Reduced Outdoor Air for Auditorium”, 2006 American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., ASHRAE Journal (Vol. 48, May 2006)

[2] “Inactivation of airborne viruses using a packed bed non-thermal plasma reactor.” T. Xia, A. Kleinheksel, E. M. Lee, Z. Qiao, K. R. Wigginton and H. L. Clack. 23 April 2019, Journal of Physics D: Applied Physics, Volume 52, Number 25.

[3] ASHRAE Standard 62.1-2016, Appendix C, ASHRAE Technical FAQ, ID 35.